News

Slewing bearings are an important component used to support and support rotating equipment. It consists of components such as inner rings, outer rings, balls or rollers, can withstand a large amount of radial and axial loads, and has excellent rotation accuracy and motion stability. This article will introduce the main knowledge points and related applications of slewing bearings.

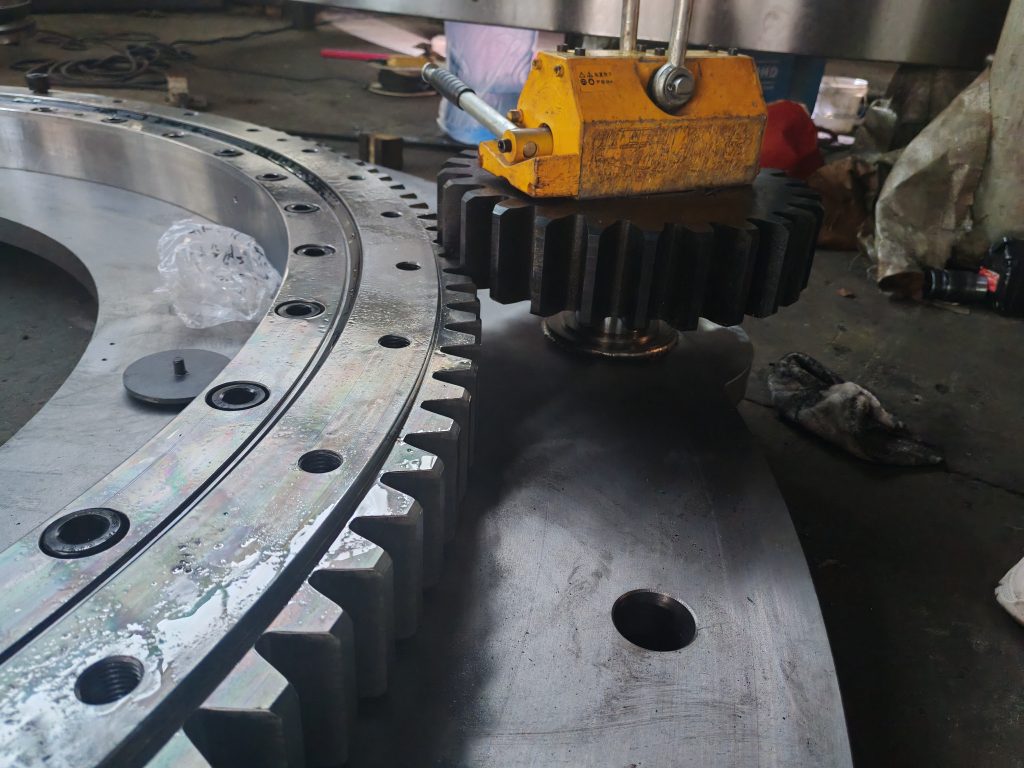

1. Structure and classification of slewing bearings There are many types of slewing bearings, the most common ones are single-row rolling ball type, double-row rolling ball type, cross rolling ball type, ball type, etc. Different structures are suitable for different application scenarios, such as rotary cranes, excavators, machine tools, etc.

2. The working principle of slewing bearings is to use rolling elements (balls or rollers) to roll between inner and outer rings to achieve rotation. Through lubrication with lubricants, rolling friction and rolling resistance are reduced, and the operating efficiency and life of slewing bearings are improved.

3. Characteristics and advantages of slewing bearings Slewing bearings have the characteristics of simple structure, easy assembly, smooth operation, large load capacity, and high rotation accuracy. Compared with traditional fixed bearings, slewing bearings have greater radial and axial load capacity and are suitable for large equipment and heavy load conditions.

4. Slewing bearings are widely used in various industrial fields, such as cranes, excavators, machine tools, port machinery, ships, wind power generation, solar power generation, etc. In these equipment, slewing bearings bear important functions such as support, rotation and torque transmission to ensure the normal operation of the equipment.

5.Selection and installation considerations of slewing bearings When selecting a slewing bearing, factors such as load type, load size, rotation speed, and working environment need to be considered to ensure the reliability and durability of the slewing bearing. When installing the slewing bearing, care should be taken to avoid over-tightening and over-loading to avoid damage to the slewing bearing.

6. Maintenance and care of slewing bearings In order to extend the service life of slewing bearings, regular maintenance and care work is required. Including regular replacement of grease, cleaning of rolling elements, inspection of seals, and measurement of rotation accuracy. These tasks help to improve the operating efficiency and reliability of slewing bearings.

7. Development trend of slewing bearings With the continuous development of industrial technology, slewing bearings are also constantly innovating and progressing. At present, some new materials and manufacturing processes are applied to slewing bearings to improve their performance and reliability. At the same time, with the development of industrial automation, slewing bearings will also be more used in robotics, intelligent manufacturing and other fields.

In summary, as an important support for rotating equipment, slewing bearings have broad application prospects and development potential. Understanding the structure, working principle and application field of slewing bearings is of great significance to improving the performance and reliability of equipment. At the same time, reasonable selection, correct installation and regular maintenance and maintenance are also the key to ensure the normal operation of slewing bearings.

Luoyang Heng Guan Bearing Technology Co., Ltd is an entity manufacturer of slewing bearings and customized non-standard machining parts. Our company integrates professional design, research and development, manufacturing, sales and service. Relying on the strong manufacturing capacity and research and development capacity, we can provide customers with one-to-one customized services and solutions.

If you have any inqury or questions for our products, please feel to contact us.

Company News / Aug 13, 2024

Importance of the difference between the two grooves of the double-row ball slewing bearing

Company News / Dec 12, 2023

PC220-8 PC300-6 PC400-6 PC600-6 PC600-8 PC700-8 swing bearing for excavator

Company News / Nov 28, 2023

Large ring gear herringbone gear manufacturingSubmit Request

PDF Request

Simply fill out the form below and the catalog will be available for download!